- Lightness

Since 88% of its volume is air, this translates to a low density, between 0.12 and 0.24 Quarts/Lb.

- Elasticity

Is the capacity to recover the initial volume after justly undergoing a deformation, such as, its utilization in corking the bottle.

- High Friction Coefficient

The cork is lined with micro suction cups that permit it to adhere to the surface without allowing it to slide.

- High Impermeability

The diffusion of liquids and gases through the cork is very difficult; it allows vapors to escape, to the outside, through the plasmodesmos.

- Fire Retardant

Non combustible does not propagate flames nor does it release incandescent particles.

- Absorbs Impacts, Aero-Elasticity

This implies that the impact not only affects the point of contacted, but also extends to the adjacent zones, which permits it to absorb the impact.

- Poison Regression Coefficient = 0

When the cork is stretched in one direction no deformation occurs in the perpendicular direction. This allows it to conform to formations of other materials that it is applied too.

- Ease of Use

Modifying the water content of the cork facilitates its management to become more elastic, and soft.

- Low Water Content

Moisture balance of the Cork with the environment is typically 6%, making impossible for microorganisms or insects to reproduce giving it unlimited durability.

- Thermal Insulation

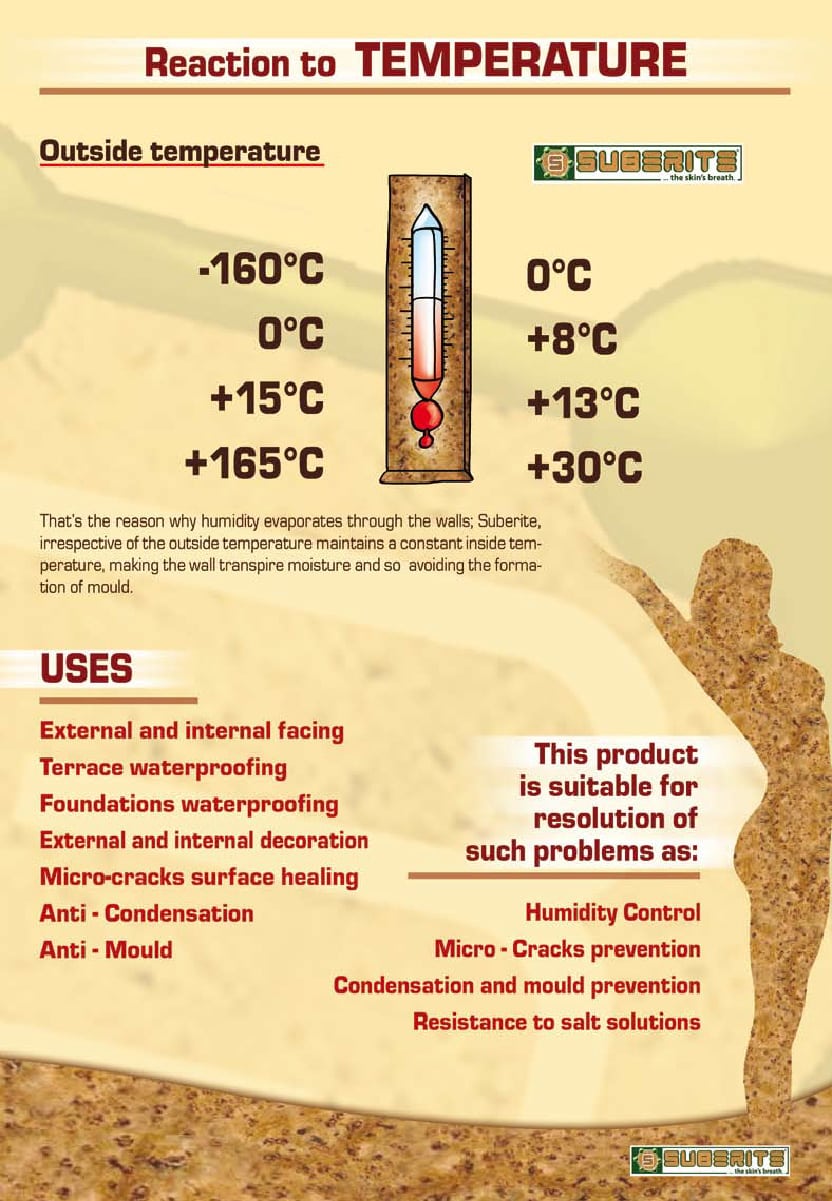

Its natural function is to protect the tree that it comes from. Its temperature range of 32° to 85 ° F. provides a resistance to heat 30 times higher than concrete thanks to its alveolar structure, low water content and lack of conductivity of its compounds.

- Acoustic Insulation

Depending on your installation and combination with other materials it reduces noise between 8 and 12 decibels. If applied on both sides of a wall it duplicates its acoustic action.

- Non Poisonous

Its lack of toxicity has allowed it to be present in mans daily life since antiquity times.

- Balance with Nature

Removal of the bark of the Cork, is performed, initially at age 40-50, and then each 9 years, and provokes rejuvenation, lengthening the life of the same tree for up to 200-500 years.

- Fauna

The cork tree or corkwood grows in natural forests which are a protective reserve for a large quantity of fauna and flora.

- Environmental Improvement

During the trimming of the bark, the cork tree releases large quantities of Oxygen, fixing the air we breathe.

- Ecological 100%

The process of extraction, manufacture and application of the cork material is done without any environmental impact.

The solution to insulation, and waterproofing problems, etc., to the homes we inhabit nature itself provides a natural way. With cork emulsion application you now have the solution within the reach of your hand.

The light colors have an peak surface temperature of 36 – 38 ° C, while the darker colors peak between 44 – 46 °C, Thermashield contain resins, an additive and dye that improves the cork data and keeps it at a cool 20-25 °C

ThermaShield has developed a specific product for the Cool Roof system with which we greatly improve the performance of the standard product, increasing and improving the following features:

- Thermal insulation

- Thermo – reflectance

- Heat transmission

- Thermal offset

As is known, between two environments at different temperatures, one establishes a heat transfer that transfers from the warmer environment to the most cold. Therefore, to ensure a comfortable environment within a building, it is necessary in winter to reduce heat losses to the exterior and in the summer reduce the heat inwards.

Irradiation

Transfer of heat from a warm body to a less warm one through a transparent means like air or emptiness. The radiant and invisible heat is transmitted through electromagnetic waves. When this energy it affects, the heat is transferred and the temperature increases. Radiation is the primary cause of heat loss in winter, 65-80% of the dispersed heat is lost through the perimeter walls and the roof. In the summer, the percentage of heat transmitted by radiation is about 93%. Our reflective insulating materials reflect 30 to 80% of the radiant energy directed towards them. The radiation expresses the transmission of electromagnetic rays in space: each body is subject to the action of infrared rays from every direction. The ability to absorb infrared rays, and therefore absorb energy, is called emission. The reflection capacity of normal building materials have an emission value of 0.82-0.9 and absorb any form over time, by irradiation Energy. ThermaShield has an emission value around 0.55 – 0.59 and therefore reflects, by reflection, a greater amount of energy.

Irradiation

Transfer of heat from a warm body to a less warm one through a transparent means like air or emptiness. The radiant and invisible heat is transmitted through electromagnetic waves. When this energy it affects, the heat is transferred and the temperature increases. Radiation is the primary cause of heat loss in winter, 65-80% of the dispersed heat is lost through the perimeter walls and the roof. In the summer, the percentage of heat transmitted by radiation is about 93%. Our reflective insulating materials reflect 30 to 80% of the radiant energy directed towards them. The radiation expresses the transmission of electromagnetic rays in space: each body is subject to the action of infrared rays from every direction. The ability to absorb infrared rays, and therefore absorb energy, is called emission. The reflection capacity of normal building materials have an emission value of 0.82-0.9 and absorb any form over time, by irradiation Energy. ThermaShield has an emission value around 0.55 – 0.59 and therefore reflects, by reflection, a greater amount of energy.